Mechanisation standardises output and lowers supervision needs for hired labour, freeing owners’ families to engage in profitable off-farm activities

A long-standing tradition in economics argues that an essential condition for economic development is the adoption of technologies that increase agricultural productivity, thereby making workers available for other sectors of the economy.1 However, the existence of contracting frictions in labour markets (Bharadwaj 2015; LaFave and Thomas 2016) may require farmers to pass on profitable labour opportunities in non-agricultural sectors to supervise workers in the field. While moral hazard problems are ubiquitous in agricultural labour (Foster and Rosenzweig 1994), technologies that mechanise agricultural operations may ease their incidence by standardising output and increasing output observability.

In a recent study (Caunedo and Kala 2021), we investigate how the adoption of mechanised practices affects needs for managerial supervision, demands for hired workers, and productivity in production. We find that the adoption of mechanisation lowers supervision needs for hired labour in stages of production other than the one being mechanised, and that the family labour freed from those needs engages in other activities outside agriculture. Using a structural model, we estimate a shadow value of family labour in the farm that is 20% of its outside option, consistent with the existence of frictions that would bind them to the family-run farm enterprise. Due to mechanisation and labour savings, total factor productivity on the farm increases by 8.8%, though total output stays the same. Our findings highlight an often-overlooked role of mechanisation in production: output standardisation, which is particularly valuable in environments with pervasive worker moral hazard.

Randomising access to mechanisation

We designed a randomised controlled trial to provide the first causal estimates of the returns to mechanisation. We study how the adoption of mechanised practices affects managerial supervision needs, demand for hired workers and productivity, by experimentally increasing access to rental markets for agricultural equipment. The experiment covered about 7,000 farmers in 190 villages in Karnataka, a state in southern India. Farmers in the treatment group received subsidy vouchers that allowed them to access approximately a third of the average mechanisation hours over the agricultural season. These vouchers could be redeemed at any point during the agricultural season and possibly transferred to other users. The subsidy scheme was conducted in partnership with one of the largest providers of agricultural equipment services in India: a public-private partnership for the creation of equipment hubs – i.e. custom hiring centers (CHCs) – throughout rural Karnataka.

The provider collects transaction data which, combined with detailed survey data on farming inputs and output, as well as labour task engagement by process of production, was used to measure the effects of access to agricultural equipment. The target population in our experiment operates at a small scale – with median land-holdings of 3.4 hectares and annual farming revenues equivalent to US$635 – and specialises in the production of rice and cotton. Through a census of more than 40000 farming households in the area, we show that these characteristics are in line with the median farmer in the population. Equipment ownership is low and farmers are relatively active in rental markets for equipment.

During the intervention, we found that treatment farmers are 30 percentage points more likely to rent agricultural equipment from CHCs as compared to control farmers. At the same time, we find no evidence that higher mechanisation from CHCs would have crowded out private suppliers. Treatment farmers increase mechanisation of their fields by 0.12 standard deviations (comparing farmers that received a voucher to those who did not), which translates into an additional 1.4 hours per acre. This mechanisation occurs entirely at the land preparation, stage which is the mechanised stage at baseline, with 99% of the sample reporting no mechanisation on downstream production stages.

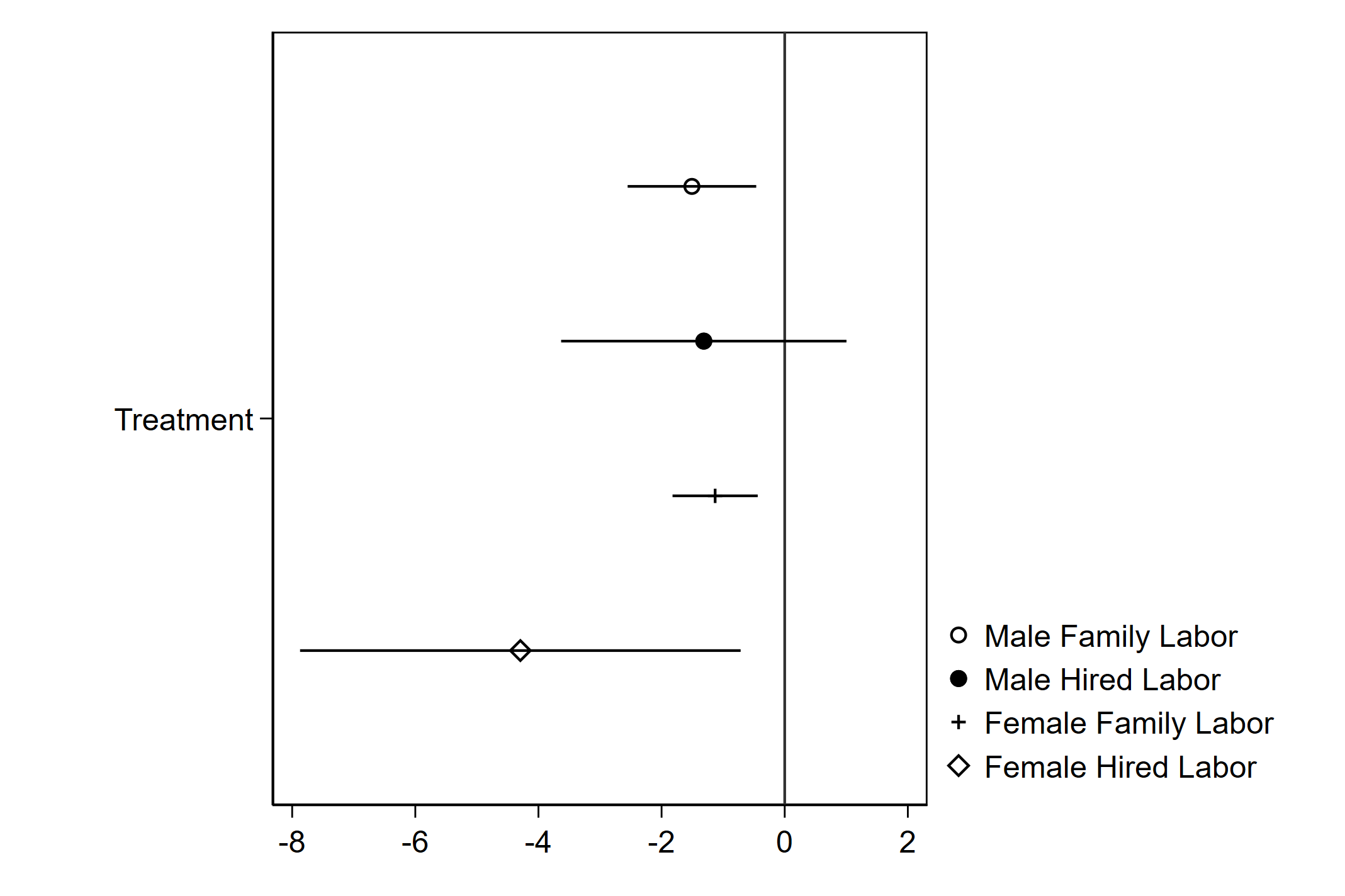

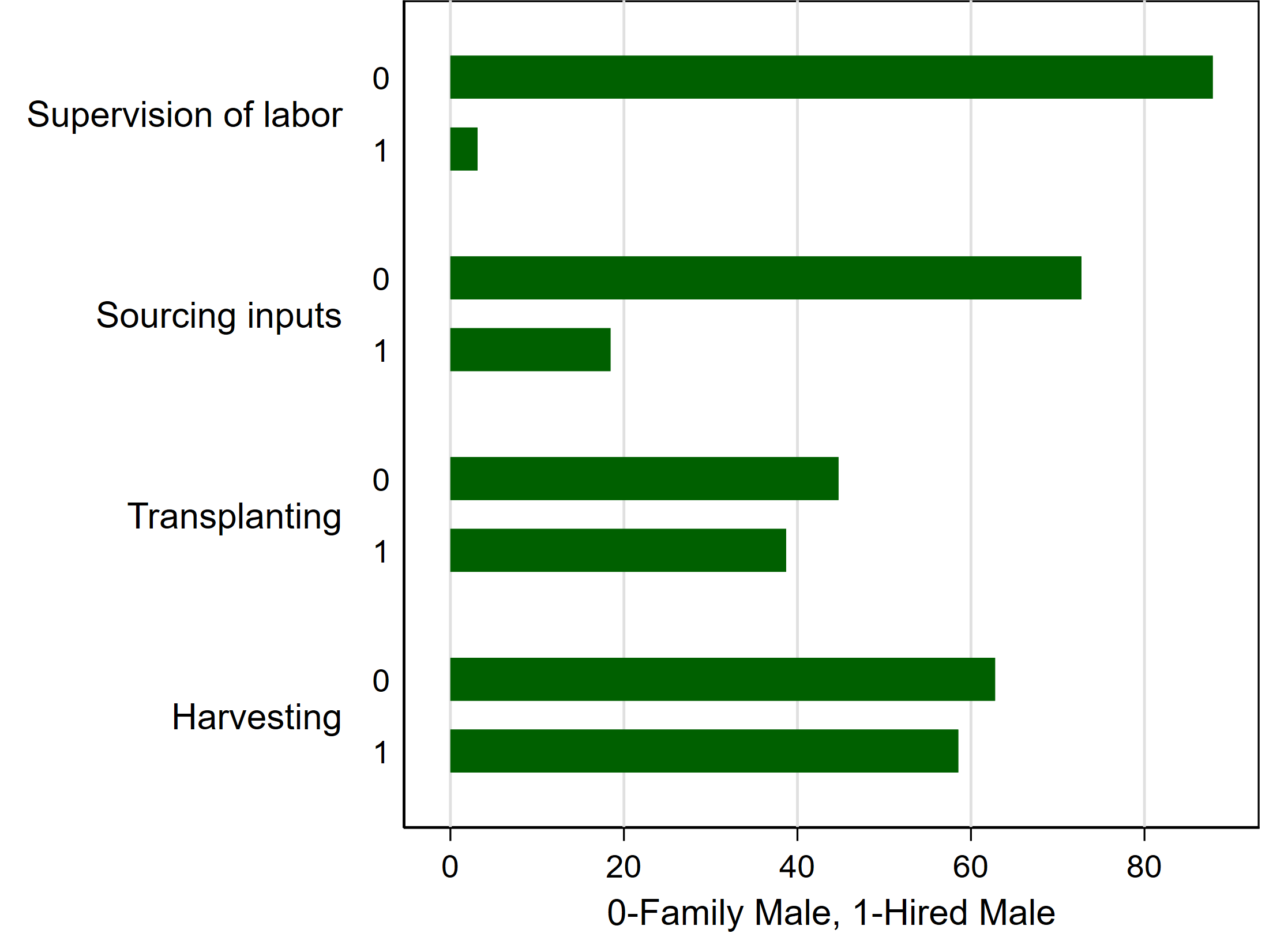

We find that mechanisation lowers labour demand across all farming stages, and disproportionately so in stages not being mechanised. Savings in non-mechanised stages account for 4.2 days of work per acre for women and 1.3 days of work per acre for men (Figure 1). At the same time, the magnitudes of labour savings are different for hired and family labour. We hypothesise that this differential effect on labour is, in part, explained by differential task engagement. Figure 2 shows the percentage of households who report either a household member or hired labour engaging in four alternative agricultural tasks. The top two tasks (supervision of labour and sourcing inputs) are the most specialised (with the greatest difference across labour types), and the bottom two tasks (transplanting and harvesting) are the least specialised. As shown in Figure 2, nearly 90% of households report supervision being done by family male labour, and only about 3% of households report hired male labour engaging in supervision. Indeed, we find that the span-of-control in the farm, measured as the number of hired workers per supervising family member, increases by 6.4 percentage points in response to the subsidy.

Figure 1 Labour savings by labour type (days per acre)

Figure 2 Prevalence of most and least specialised tasks

Note: Each bar denotes the proportion of households who reported that task being done by a household member (bars labelled 0) or hired labour (bars labelled 1). The level of task specialisation is measured by the difference in the task engagement between hired and family labour.

While the freed supervision labour could be allocated to other activities in the field, home production, or other activities outside the farm, we find evidence of the latter. We find no differential engagement of family labour in fields owned by others, and a 3.6% increase in non-farm income for treatment households relative to control farmers. This finding is consistent with shifts in labour supply outside agriculture.

Studying channels and welfare

To study the channels through which mechanisation affects farming households’ decisions, as well as to identify the magnitude of key inputs to the returns to mechanisation at scale – i.e. the returns to capital and the shadow value of family labour on the farm – we build a structural model of farmers’ labour supply decisions in the family enterprise and outside of it. We model farming as a multi-stage production technology where land preparation can be performed with machines or with labour, as in a standard task-replacement model (Acemoglu and Zilibotti, 2001). Farmers choose consumption and whether to work in the farm or in non-agriculture over multiple periods along the agricultural season.

We use the reduced-form estimates from the experiment and the structural predictions of the model to measure the marginal returns to capital, which we estimate at 8.8% per season under the assumption of frictionless rental markets. These marginal returns to capital can be as high as 15.5% when allowing for frictions in equipment rental markets. Estimating marginal returns to capital is a challenging task because the amount of capital services used by the enterprise typically depends on the owner’s own ability, and the technology he operates, both of which are unobserved. In the literature, a common strategy to overcome this endogeneity is to incentivise exogenous shifts in the demand for capital via randomised access to capital. A methodological contribution of our study is to show that this randomisation does not overcome the problem because the adoption of more capital services indeed shifts the technology and productivity of the farm – i.e. the instrument does not satisfy the excludability restrictions.

We also use the model to measure the shadow value of family labour, which we estimate is 20% below farmers’ outside option in non-agriculture. This gap is consistent with contracting frictions that bind family workers to the operation of the farm. Finally, we estimate the residual (endogenous) productivity change that is consistent with the experimental estimates of changes to employment, capital and value-added, and measure an increase in total factor productivity of 6.6% per season.

Given that the intervention shifted incentives to work in non-agriculture through farming households’ optimal leisure allocations, income changes are not sufficient to assess welfare. Therefore, we further explore what the welfare impact of the intervention is. We use the model’s predictions to construct a measure of consumption-equivalent welfare for the average farmer in the economy and find that the intervention raised welfare by 0.9%. The main contributors to the welfare gains were the changes in total factor productivity mentioned above, followed by the improvement in the span-of-control in the farm and its impact on labour supply decisions.

Moving forward

The measurement of the marginal returns to adoption of mechanised practices are of first-order relevance to understanding the effect of policies directed towards capital intensification. Our results indicate that, in addition to its standard labour-saving effects, increased mechanisation can reduce contracting frictions for hired labour by standardising output, releasing family labour off the farm, and ultimately increasing welfare.

The productivity and welfare gains from mechanising production can, in turn, feed back into incentives for land consolidation, as well as for mechanisation of production stages other than land preparation. While these effects were outside the scope of our study, further analysis would deepen our understanding of the role of mechanisation for unlocking economic development.

References

Acemoglu, D and F Zilibotti (2001), “Productivity differences”, The Quarterly Journal of Economics 116(2): 563–606.

Baumol, W J (1967), “Macroeconomics of unbalanced growth: The anatomy of urban crisis”, The American Economic Review 57(3): 415–426.

Bharadwaj, P (2015), “Fertility and rural labor market inefficiencies: Evidence from India”, Journal of Development Economics 115: 217–232.

Caunedo, J, and N Kala (2021) “Mechanizing Agriculture", NBER Working Paper 29061.

Foster, A D and M R Rosenzweig (1994), “A test for moral hazard in the labor market: Contractual arrangements, effort, and health”, The Review of Economics and Statistics 76(2): 213–227.

Gollin, D, S Parente and R Rogerson (2002), “The Role of Agriculture in Development”, American Economic Review 92(2): 160–164.

Kongsamut, P, S Rebelo and D Xie (2001), “Beyond balanced growth”, The Review of Economic Studies 68(4): 869–882.

LaFave, D and D Thomas (2016), “Farms, families, and markets: New evidence on completeness of markets in agricultural settings”, Econometrica 84(5): 1917– 1960.

Ngai, L R and C A Pissarides (2007), “Structural change in a multisector model of growth”, American Economic Review 97(1): 429–443.

Timmer, C P (1988), “The agricultural transformation”, in Handbook of Development Economics, Vol. 1, Elsevier.

Endnotes

1 An extensive literature includes Baumol (1967), Timmer (1988), Kongsamut et al. (2001) and Ngai and Pissarides (2007). Gollin et al. (2002) quantify that 54% of the growth in GDP- per-capita across countries between 1960 and 1990s is due to growth in productivity within agriculture alone.